17+ Manufacturing Industry Trends and Statistics

Fact checked 2026 | 👨🎓Cite this article.

The manufacturing industry is rapidly evolving, driven by technological advances and changing market demands. Future trends highlight increased adoption of AI, IoT, and smart automation to enhance efficiency and sustainability.

Data and statistics play a crucial role in tracking these shifts, helping businesses anticipate challenges and opportunities. This article examines key manufacturing trends over the years, highlighting how data-driven insights are shaping the industry's future growth and innovation.

Historical Growth and Output Trends in Manufacturing

Fact checked 2026 | 👨🎓Cite this stat. This image is copyright free.

Analysis of manufacturing output growth over recent years

- Global manufacturing output grew by 1% in Q4 2024 quarter-over-quarter, following gains of over 0.5% in each of the two previous quarters, signaling a gradual recovery after sluggish 2023 and early 2024 periods.

- The global manufacturing market size increased from USD 13.5 trillion in 2023 to USD 14.16 trillion in 2024, with projections to reach USD 20.76 trillion by 2031, reflecting a compound annual growth rate (CAGR) of 4.9%.

- In 2024, the global manufacturing economy expanded by only 0.6%. However, forecasts for 2025 indicate a rebound, with steady growth expected to continue through 2028 despite a slight dip in 2026.

- The U.S. manufacturing sector is projected to grow by 4.2% in 2025, with capital expenditures expected to rise by 5.2%, signaling renewed investment and expansion following recent challenges.

Key Industry Segments Contributing to Growth

- The Automobiles & Auto Parts sector experienced a steep global output contraction in early 2025, marking the sharpest decline since November 2022; however, European producers ended a 21-month production decline in March 2025, stabilizing output.

- The smart manufacturing market is projected to nearly double from USD 233.33 billion in 2024 to USD 479.17 billion by 2029, driven by automation, robotics, and IoT adoption.

Statistical Projections for the Coming Years

- By 2031, the global manufacturing market is expected to hit USD 20.76 trillion, up from USD 14.16 trillion in 2024, with a CAGR of 4.9% over the period.

- The global smart manufacturing market is expected to grow from USD 233.33 billion in 2024 to USD 479.17 billion by 2029, reflecting a rapid digital transformation.

- Employment in manufacturing increased by 498,000 jobs globally in 2024, with a total workforce of 12.3 million, indicating steady labor market expansion despite ongoing talent shortages.

Technological Innovations Transforming Manufacturing

Adoption of Advanced Technologies: IoT, AI, Robotics, 3D Printing

- In 2024, manufacturing companies allocated 30% of their operating budgets to technology investments, up from 23% in 2023, with cloud computing, generative AI, and 5G delivering the highest ROI.

- 57% of manufacturers use cloud computing and data analytics, while 46% haveadopted Industrial IoT (IIoT) solutions, marking a steady increase from 40% adoption rates in 2023.

- Robotics and automation were adopted by 37% of manufacturers in 2024, up from 31% in 2023, driven by the need to reduce labor costs and improve operational efficiency.

- AI and machine learning technologies are integrated by 19% of manufacturing firms, with 40% prioritizing AI and automation in their 2025 digital transformation plans, compared to 28% in 2023.

- 12% of manufacturers have fully deployed AI systems, while 57% are actively researching AI use cases and an additional 11% plan deployment within 12 months.

- 3D printing usage expanded notably in the automotive and aerospace sectors, producing lightweight components; the global additive manufacturing market is forecasted to grow from USD 15 billion in 2023 to USD 35 billion by 2027, more than doubling in four years.

- The medical devices industry has seen a 25% increase in 3D-printed prosthetics production since 2022, with emerging adoption in the construction and consumer electronics sectors.

Impact of Digital Transformation and Smart Factories

- Smart manufacturing technology adoption focuses on sensors, data capture, and automation, with 41% of manufacturers planning investments in factory automation hardware and 34% prioritizing active sensors in 2025, up from 30% and 25%, respectively, in 2023.

- Vision systems are targeted by 28% of manufacturers for investment, up from 20% in 2023, thereby enhancing quality control and operational efficiency.

- Enterprise standards adoption for data and architecture has increased: 54% of manufacturers use unified data models, and 45% apply architecturalstandards, both of which have risen by approximately 10 percentage points since 2022.

- The global smart manufacturing market is projected to nearly double from USD 233 billion in 2024 to USD 479 billion by 2029, reflecting the rapid integration of digital technologies.

Role of Emerging Technologies: Generative AI and Extended Reality (XR)

- Generative AI investments surged, with manufacturers allocating over 30% more budget in 2024 compared to 2023, focusing on product design, development, and simulation.

- Extended Reality (XR) adoption is growing, with more than 25% of manufacturers deploying XR for training and maintenance, up from 15% in 2022.

- Software-driven manufacturing is expanding beyond factory floors, with over 50% of manufacturers integrating software solutions to connect products in the field, a 20% increase since 2022.

Operational Trends: Predictive Maintenance and Efficiency Improvements

Fact checked 2026 | 👨🎓Cite this stat. This image is copyright free.

Rise of Predictive Maintenance Using AI and Sensors

- The global predictive maintenance market is valued at USD 10.93 billion in 2025 and is expected to reach USD 44.00 billion by 2032, growing at a CAGR of 22.0% from 2025 to 2032.

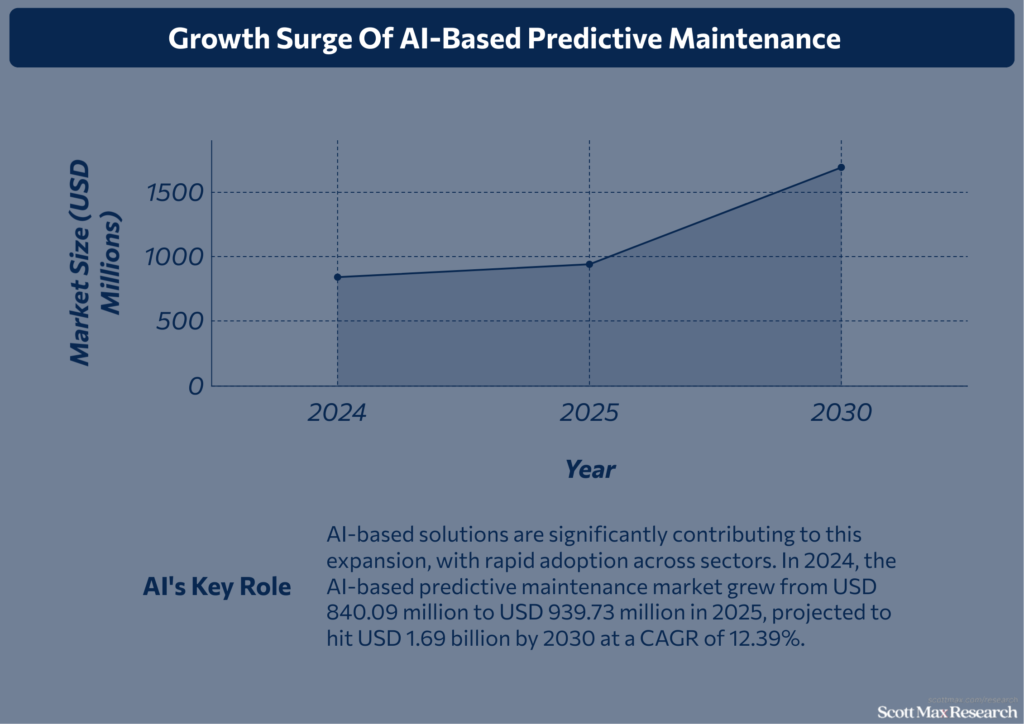

- In 2024, the AI-based predictive maintenance market grew from USD 840.09 million to USD 939.73 million in 2025, projected to hit USD 1.69 billion by 2030 at a CAGR of 12.39%.

- Predictive maintenance decreases costs by 12%, improves asset availability by 9%, extends asset lifetime by 20%, and reduces safety and quality risks by 14%, according to a study of 268 European companies.

- The market size for predictive maintenance is forecasted to grow from USD 9.3 billion in 2024 to USD 11.88 billion in 2025 at a CAGR of 27.6%, with projections reaching USD 33.36 billion by 2029.

- By 2025, the adoption of predictive maintenance is expected to grow by 25% annually, driven by advancements in AI and IoT.

Benefits of Reducing Downtime and Costs

- Unplanned downtime costs manufacturers approximately USD 260,000 per hour, highlighting the critical need for predictive maintenance.

- Predictive maintenance can reduce equipment downtime by 30%, saving the manufacturing sector USD 50 billion annually by 2025.

- Companies implementing predictive maintenance have seen a reduction in repair time of over 90% and a significant decrease in unplanned downtime.

- Maintenance cost savings average 12% with predictive maintenance, compared to reactive or preventive approaches.

- Predictive maintenance extends the lifespan of aging assets by 20%, reducing capital expenditure on replacements.

- Safety, health, environmental, and quality risks are reduced by 14% with the adoption of predictive maintenance.

Integration with ERP Systems and Hyper-automation

- The integration of predictive maintenance with enterprise resource planning (ERP) systems is a key driver of market growth, facilitating seamless maintenance scheduling and resource allocation.

- Approximately 50% of organizations still rely on manual or spreadsheet-based maintenance management, limiting efficiency gains.

- Hyper-automation, which combines AI, machine learning, and IoT, is being increasingly deployed to automate maintenance workflows, with over 40% of manufacturers planning to invest in automation technologies by 2025.

Summary of Market and Operational Impact

- The predictive maintenance market is projected to quadruple from USD 10.93 billion in 2025 to USD 44 billion by 2032, driven by the adoption of AI, IoT, and sensor technology proliferation.

- A 30% reduction in downtime translates to USD 50 billion in annual savings for manufacturers by 2025.

- Maintenance cost reductions of 12%, asset life extension by 20%, and improved operational availability by 9% demonstrate tangible improvements in efficiency.

- Integration with ERP and hyper-automation accelerates maintenance optimization, although 50% of firms still rely on manual processes, indicating room for growth.

- Workforce shortages, with a projected global shortfall of 2 million skilled maintenance technicians by 2025, further drive the adoption of automation and predictive maintenance.

Worldwide Market Dynamics and Workforce Trends in Manufacturing

Labor Market Stabilization and Employment Trends

- The global manufacturing workforce is projected to reach 157 million employees in 2025, growing at a CAGR of 1.65% from 2025 to 2029, up from approximately 150 million in 2023.

- The quits rate in U.S. manufacturing declined from 1.8% in January 2024 to 1.6% in September 2024, indicating improved labor stability.

- Employment in key manufacturing sectors in 2025 includes:

- Auto parts and accessories: 9.61 million jobs

- Engineering services: 8.51 million jobs

- Plastic product and packaging manufacturing: 7.27 million jobs

Supply Chain Adjustments and Workforce Impact

- Manufacturers continue to adjust supply chains to mitigate disruptions, investing in nearshoring and diversification strategies; these shifts influence labor demand regionally.

- Automation adoption is increasing to counterbalance labor shortages, with 40% of manufacturers planning investments in automation technologies in 2025.

- Despite automation, demand for higher-skilled roles in the workforce is rising, necessitating expanded training and upskilling programs to close the skills gap.

- Global manufacturing employment growth is uneven, with emerging markets like Vietnam and Mexico experiencing job growth, while some developed economies report modest declines or stabilization.

Summary of Workforce and Market Dynamics

- Manufacturing employment is stabilizing globally, with 157 million workers expected in 2025 and moderate growth forecasted through 2029.

- Skills shortages threaten to leave up to 1.9 million jobs unfilled by 2030, emphasizing the need for workforce development.

- Rising labor costs, with compensation increases near 4% annually, challenge manufacturers’ cost structures.

Sustainability and Environmental Impact in Manufacturing

Fact checked 2026 | 👨🎓Cite this stat. This image is copyright free.

Increasing Focus on Sustainable Manufacturing Practices

- The global manufacturing industry was valued at USD 14.16 trillion in 2024, with sustainable manufacturing growing at an annual rate of 3.34%, driven by over 1,000 startups innovating eco-friendly solutions.

- In 2025, 72% of global consumers expressed a willingness to pay more for sustainable products, up from 65% in 2023, prompting manufacturers to prioritize sustainability.

- Over 640 sustainability-related patents and 410 research grants were filed in 2024, marking a 13.93% annual increase in sustainable innovation, with China and the U.S. dominating patent issuance.

Investments in Energy and Material Efficiency

- Manufacturing firms increased sustainability investments by 25% in 2024 compared to 2023, focusing on energy-efficient machinery, waste reduction, and circular manufacturing tools.

- AI-driven smart manufacturing technologies reduced energy consumption by an average of 15% in pilot programs conducted in 2024 compared to traditional manufacturing setups.

- Over 50% of manufacturers integrated energy optimization software and smart manufacturing systems in 2024, a rise from 38% in 2022, which improved operational efficiency and reduced emissions.

- Private equity firms invested more than USD 1.66 billion in AI-driven and eco-friendly manufacturing startups in 2024, reflecting growing capital flow into sustainable technologies.

Industry Commitment to Zero-Emission Production Systems and Green Innovation

- Strategic alliances have been formed to develop electric underground mining trucks, aiming for net-zero carbon emissions by 2050, with the first prototype scheduled for delivery in October 2024.

- Industrial product manufacturers are emphasizing electrification, with clean energy solutions expected to drive growth. Companies have revised their emissions targets to reduce Scope 1 emissions by 30% by 2030, compared to 2020 levels.

- AI and machine learning applications contributed to a 30% reduction in greenhouse gas emissions in factories deploying predictive analytics and real-time monitoring in 2024.

- Sustainability-linked financing models increased by 40% in 2024, incentivizing manufacturers to meet stringent environmental goals and improve ESG compliance.

- The sustainable manufacturing sector added over 16,000 new jobs in 2024, bringing the total global employment to 304,000, reflecting sector growth and an increased focus on green skills.

Summary of Sustainability Trends and Market Impact

- The sustainable manufacturing market is projected to grow from USD 14.16 trillion in 2024 to USD 20.76 trillion by 2031 at a CAGR of 4.9%, driven by regulatory mandates and consumer demand.

- Over 1,400 funding rounds closed in 2024, with an average investment exceeding USD 23 million per round, signaling robust investor confidence in sustainable manufacturing.

Conclusion

The manufacturing industry continues to evolve, driven by technological innovation, sustainability efforts, and shifting market demands. With global output projected to reach $36.7 trillion by 2029 and a steady CAGR, the sector is poised for growth despite recent challenges.

Advances in automation, AI, and additive manufacturing are reshaping production while increased investment and a growing workforce support expansion. Embracing data-driven strategies and sustainable practices will be key for manufacturers to stay competitive and thrive in the dynamic global landscape ahead.

Insights On Manufacturing Industry Trends and Statistics

What are the key manufacturing trends shaping 2025?

The top trends include the rise of smart factories, increased use of AI and edge computing, hyperpersonalization through microfactories, and a strong focus on sustainability and supply chain resilience.

How is technology impacting manufacturing efficiency?

Technologies such as AI, IoT, robotics, and predictive maintenance are driving efficiency by enabling real-time insights, reducing downtime, and facilitating flexible, on-demand production.

What role does data play in manufacturing today?

Data is crucial for decision-making, with 75% of organizational data expected to be processed at the edge by 2025, facilitating faster, actionable insights that support customization and operational agility.

How is the workforce evolving in manufacturing?

Despite the easing of the labor market, challenges persist with skills gaps and rising compensation costs. Future roles will require a combination of technical, digital, and soft skills to meet the evolving needs of production.

What are the sustainability priorities in manufacturing?

Manufacturers are prioritizing carbon neutrality, energy efficiency, and circular economy practices, recognizing sustainability as both a regulatory necessity and a competitive differentiator.

References & Citations:

- Global manufacturing sectors struggle in opening quarter of 2025 amid strengthening headwinds

Sian Jones (Apr 2025), Global manufacturing sectors struggle in opening quarter of 2025 amid strengthening headwinds - Global Manufacturing Rebound Predicted in 2025

Farm Equipment Manufacturers Association (Jun 2025), Global Manufacturing Rebound Predicted in 2025 - Manufacturing Industry Outlook 2025: Key Data & Innovation Insights

Yasmin Tamanna (Jan 2025), Manufacturing Industry Outlook 2025: Key Data & Innovation Insights - 27 Manufacturing Statistics USA & Global [2025]

Godlan, Inc (2025), 27 Manufacturing Statistics USA & Global [2025] - 2025 Manufacturing Industry Outlook

Deloitte Research Center for Energy & Industrials (Nov 2024), 2025 Manufacturing Industry Outlook - 2025 Smart Manufacturing and Operations Survey: Navigating challenges to implementation

Deloitte Research Center for Energy & Industrials (May 2025), 2025 Smart Manufacturing and Operations Survey: Navigating challenges to implementation - Top 10 Recent Trends in Manufacturing Technology to Watch in 2025

Magdalena Narewska (Jan 2025), Top 10 Recent Trends in Manufacturing Technology to Watch in 2025 - 2025 Manufacturing Predictions: The Rise Of Industry 4.0, Data Convergence, Changed Regulatory Climate And More

Simon Dae Oong Kim (Jan 2025), 2025 Manufacturing Predictions: The Rise Of Industry 4.0, Data Convergence, Changed Regulatory Climate And More - Revealed: Key Manufacturing Industry and Technology Trends for North America in 2025

Aptean Staff Writer (Dec 2024), Revealed: Key Manufacturing Industry and Technology Trends for North America in 2025 - New Research from Revalize Predicts Major Technology-Driven Growth for the Manufacturing Industry in 2025 and Beyond

ManufacturingTomorrow (Feb 2025), New Research from Revalize Predicts Major Technology-Driven Growth for the Manufacturing Industry in 2025 and Beyond - New research reveals manufacturers eager to adopt smart manufacturing technologies – but face deployment challenges

Bill Tanner (Jun 2025), New research reveals manufacturers eager to adopt smart manufacturing technologies – but face deployment challenges - Predictive Maintenance Market Analysis & Forecast: 2025-2032

Coherent Market Insights (Feb 2025), Predictive Maintenance Market Analysis & Forecast: 2025-2032 - Maintenance statistics and trends 2025

Infraspeak Team (Nov 2024), Maintenance statistics and trends 2025 - AI-Based Predictive Maintenance Market Report 2025-2030: A Projected US$1.69 Billion Landscape – Businesses Must Invest in Cloud and Edge Technologies for Future Success

Research and Markets (Apr 2025), AI-Based Predictive Maintenance Market Report 2025-2030: A Projected US$1.69 Billion Landscape – Businesses Must Invest in Cloud and Edge Technologies for Future Success - Predictive Maintenance Trends in Manufacturing for 2025

Cerexio (Mar 2025), Predictive Maintenance Trends in Manufacturing for 2025 - Predictive Maintenance Market Report 2025

Research and Markets (Mar 2025), Predictive Maintenance Market Report 2025 - Predictive Maintenance: Targeting 30% Downtime Reduction and $50 Billion in Annual Savings by 2025

Keev Capital (Jan 2025), Predictive Maintenance: Targeting 30% Downtime Reduction and $50 Billion in Annual Savings by 2025 - 80+ Sustainability Statistics for 2025: Ultimate List

Michael Vereb (May 2025), 80+ Sustainability Statistics for 2025: Ultimate List - 2025 Manufacturing Sustainability: Challenges and Solutions

Ashley Taylor (Mar 2025), 2025 Manufacturing Sustainability: Challenges and Solutions - Manufacturers’ 2025 sustainability priorities

Michelle No (Feb 2025), Manufacturers’ 2025 sustainability priorities - The Landscape of Sustainable Manufacturing 2025

Dialectica (2025), The Landscape of Sustainable Manufacturing 2025 - The top 3 sustainable practices shaping the future of manufacturing in 2025

Thought leadership, INCIT (Jan 2025), The top 3 sustainable practices shaping the future of manufacturing in 2025 - Sustainable Manufacturing Report 2025: Key Insights & Innovations

StartUs Insights (2025), Sustainable Manufacturing Report 2025: Key Insights & Innovations - Top Manufacturing Trends for 2025: AI, Cloud, and Sustainability

Mahesh Madhav Mahajan (Mar 2025), Top Manufacturing Trends for 2025: AI, Cloud, and Sustainability - Manufacturing jobs as a share of total employment

Our World in Data (Aug 2024), Manufacturing jobs as a share of total employment - Global Manufacturing Job Market Trends & Future Insights

Sarah Lee (Apr 2025), Global Manufacturing Job Market Trends & Future Insights - Future of Jobs Report 2025

World Economic Forum (Jan 2025), Future of Jobs Report 2025 - Biggest Industries by Employment in Global in 2025

IBISWorld (2025), Biggest Industries by Employment in Global in 2025 - Manufacturing – Worldwide

Statista (2025), Manufacturing – Worldwide